Overview

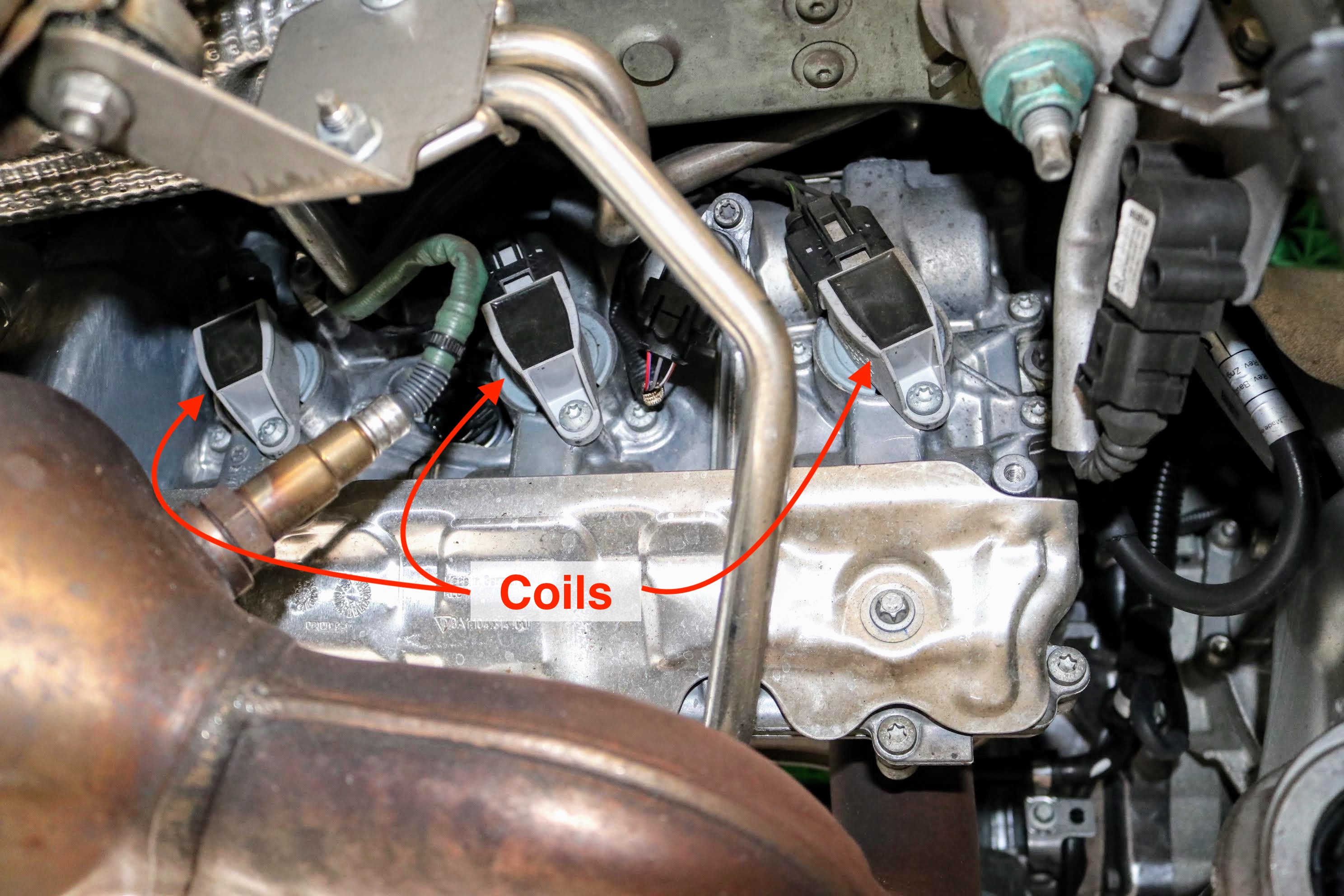

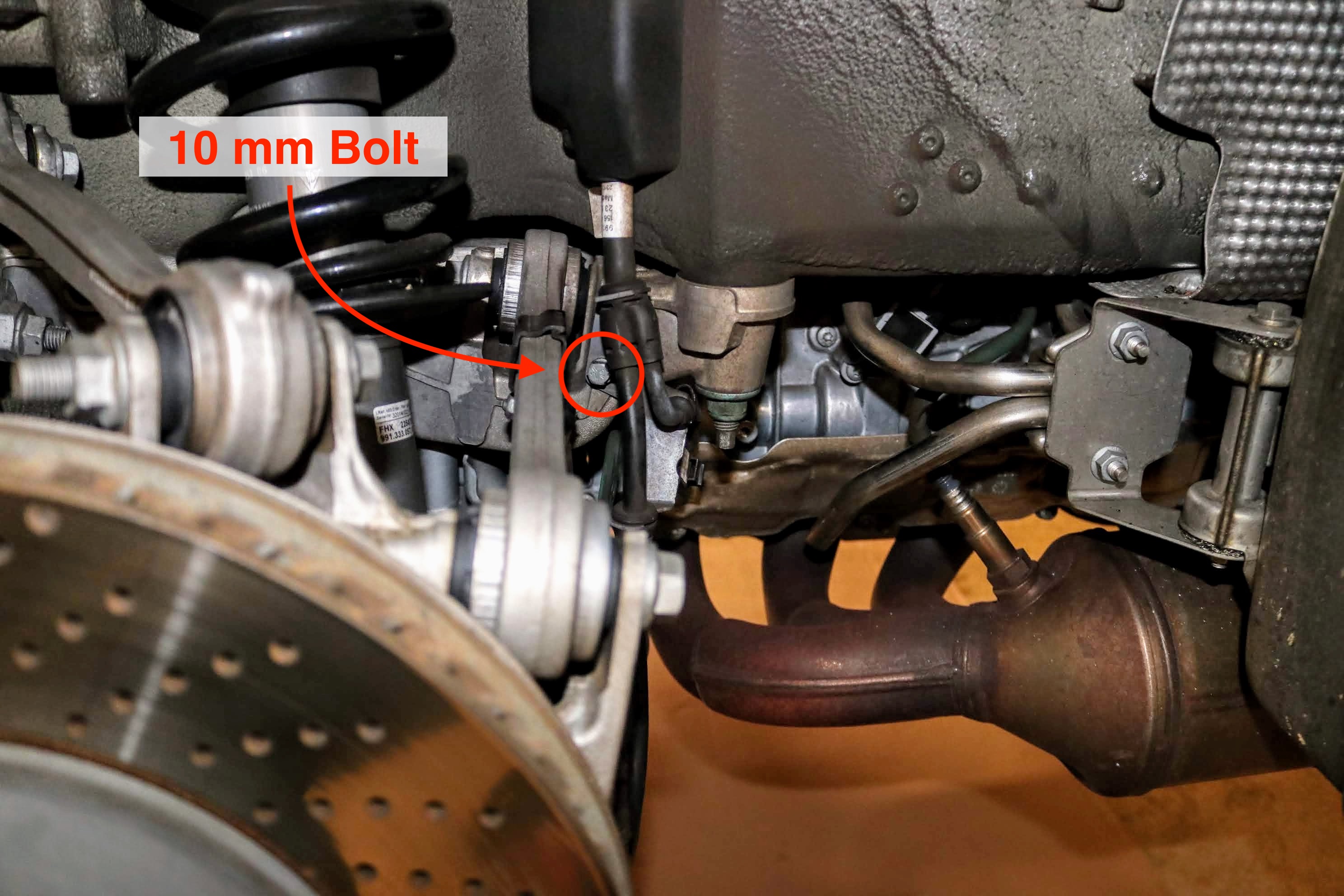

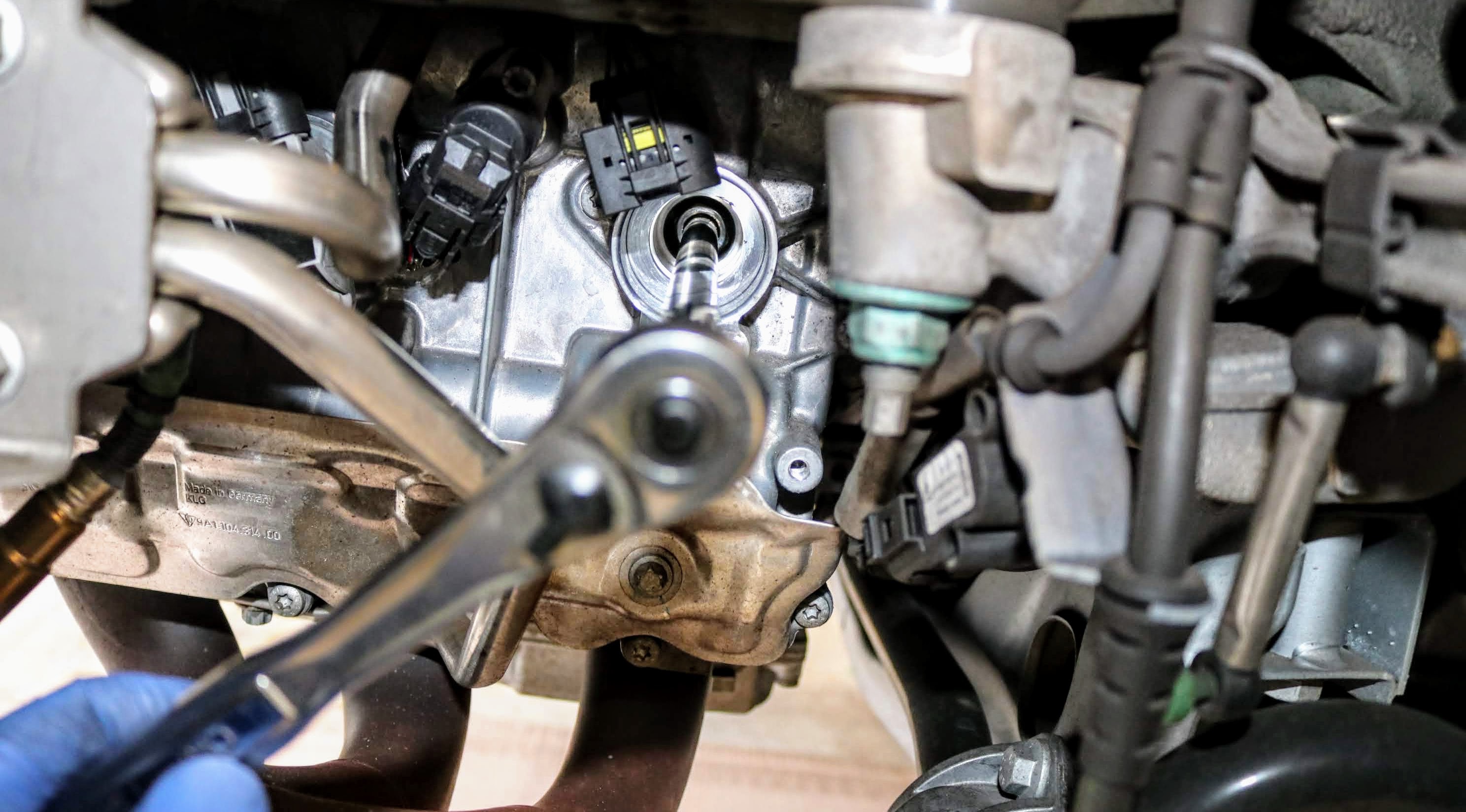

This guide goes through the steps we used to replace all six spark plugs on a Porsche 911 (991.1). Porsche states to replace spark plugs every 4 years, or every 40,000 miles (60,000 kms). Change the spark plugs on Porsche's flat six engine is not any different than any other engine. The difficulty is gaining access to all of the spark plugs. It took plenty of patience and finesse to work in such a tight area. With some creativity, plenty of extensions, universal joint, and various types of 3/8" ratchets, such as this 3/8" drive extendable ratchet, we were able to get the job done without completely ruining our knuckles. When you were at the hardware store and saw that weird looking ratchet or extension, this is the type of job when those tools earn their keep ten fold!

One final note, since this maintenance is usually done at the same time as the engine oil change, be sure to change the spark plugs FIRST, before the engine is hot.

Parts Used

| Part | Quantity | Part No. | Links to ones we used |

|---|---|---|---|

| Bosch Spark Plugs (set of 6) | 1 | Bosch FGR5NQE | Amazon |

Tools Used

| Tool | Link |

|---|---|

| Quick Jack BL-5000XL portable lift | Amazon |

| Jack Stands | Amazon |

| 3/8" Drive Ratchet | Amazon |

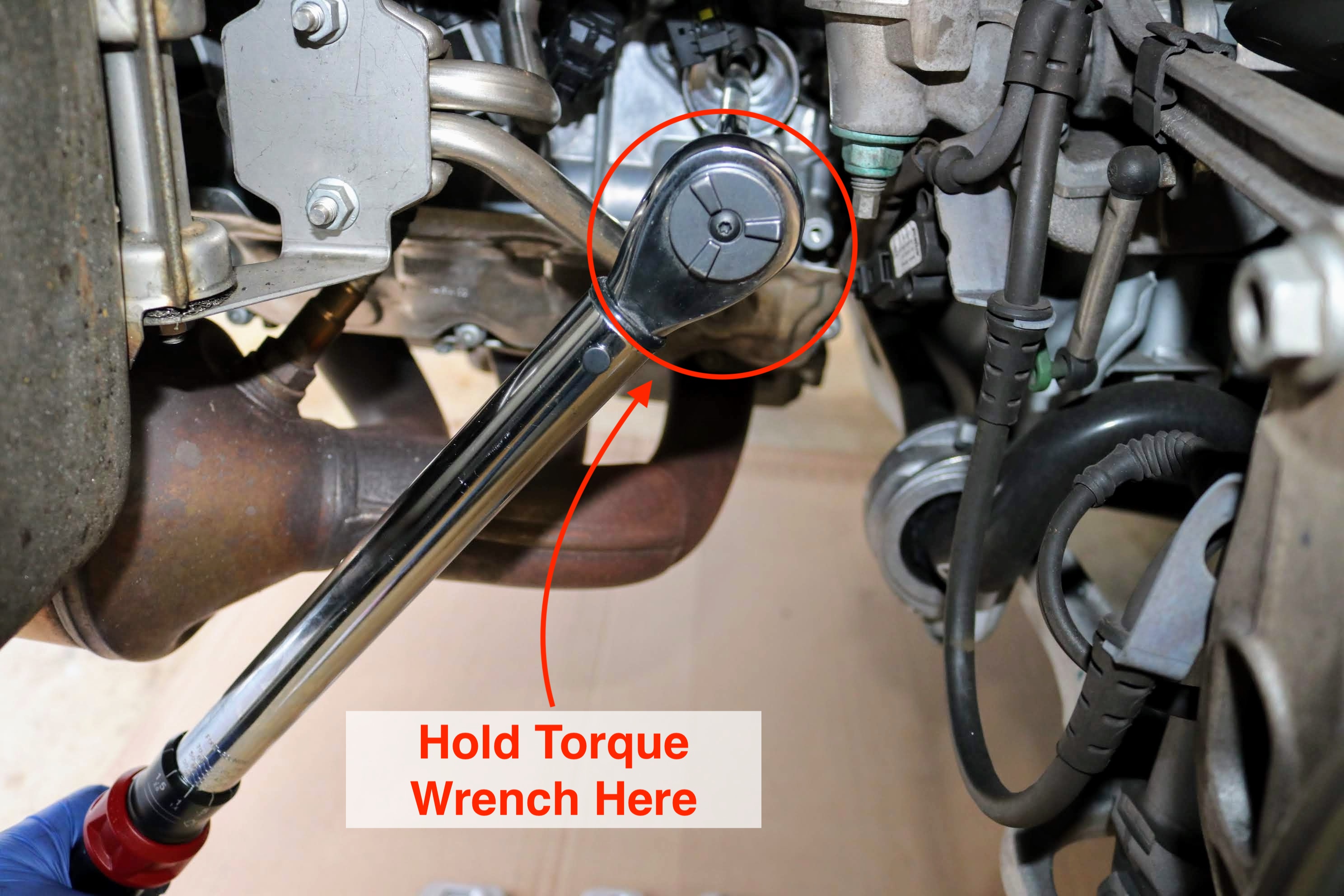

| 3/8" Drive Torque Wrench | Amazon |

| 3/8" Drive Extension | Amazon |

| 3/8" Drive Universal Joint | Amazon |

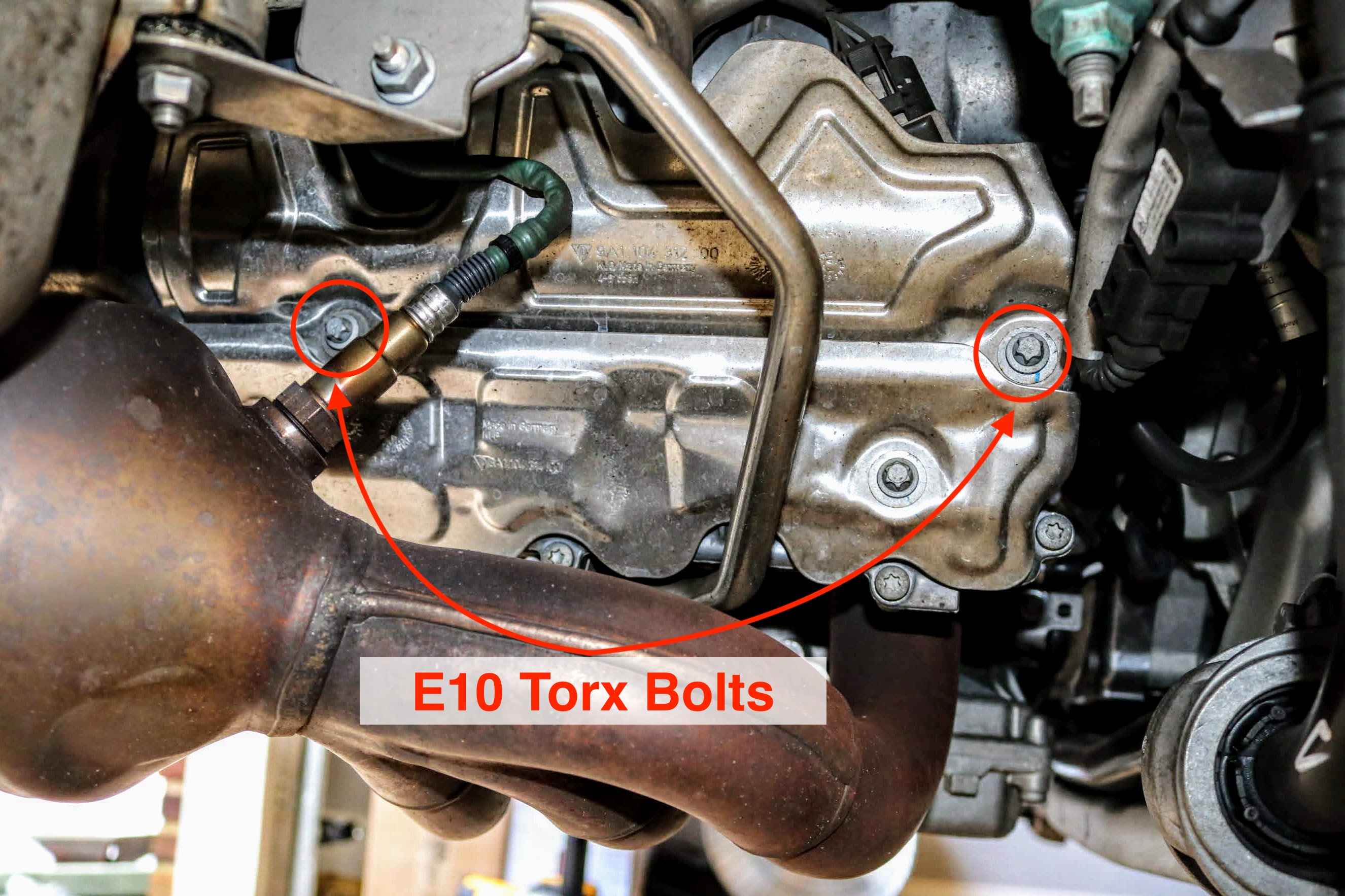

| E10 (External Torx) Socket | Amazon |

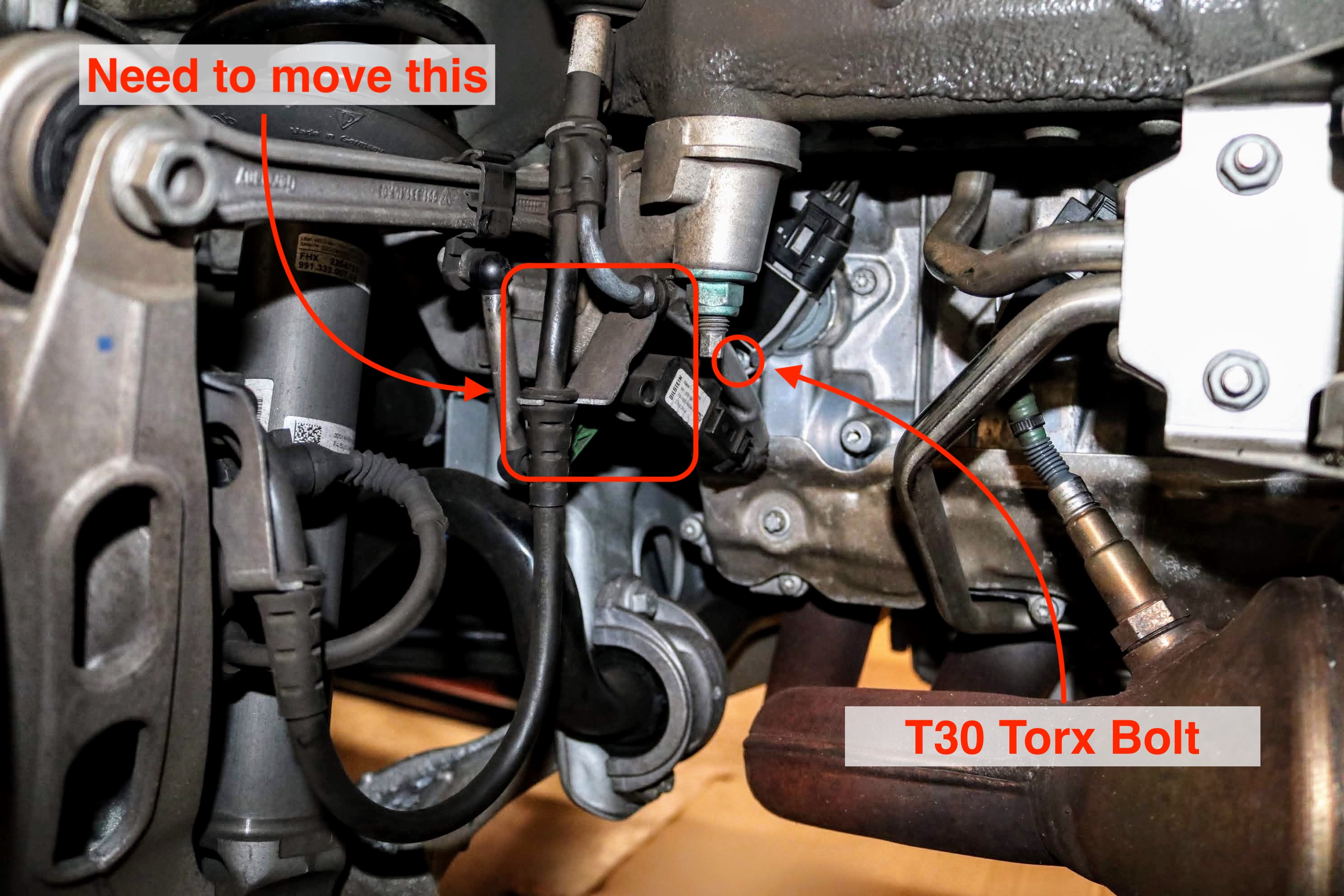

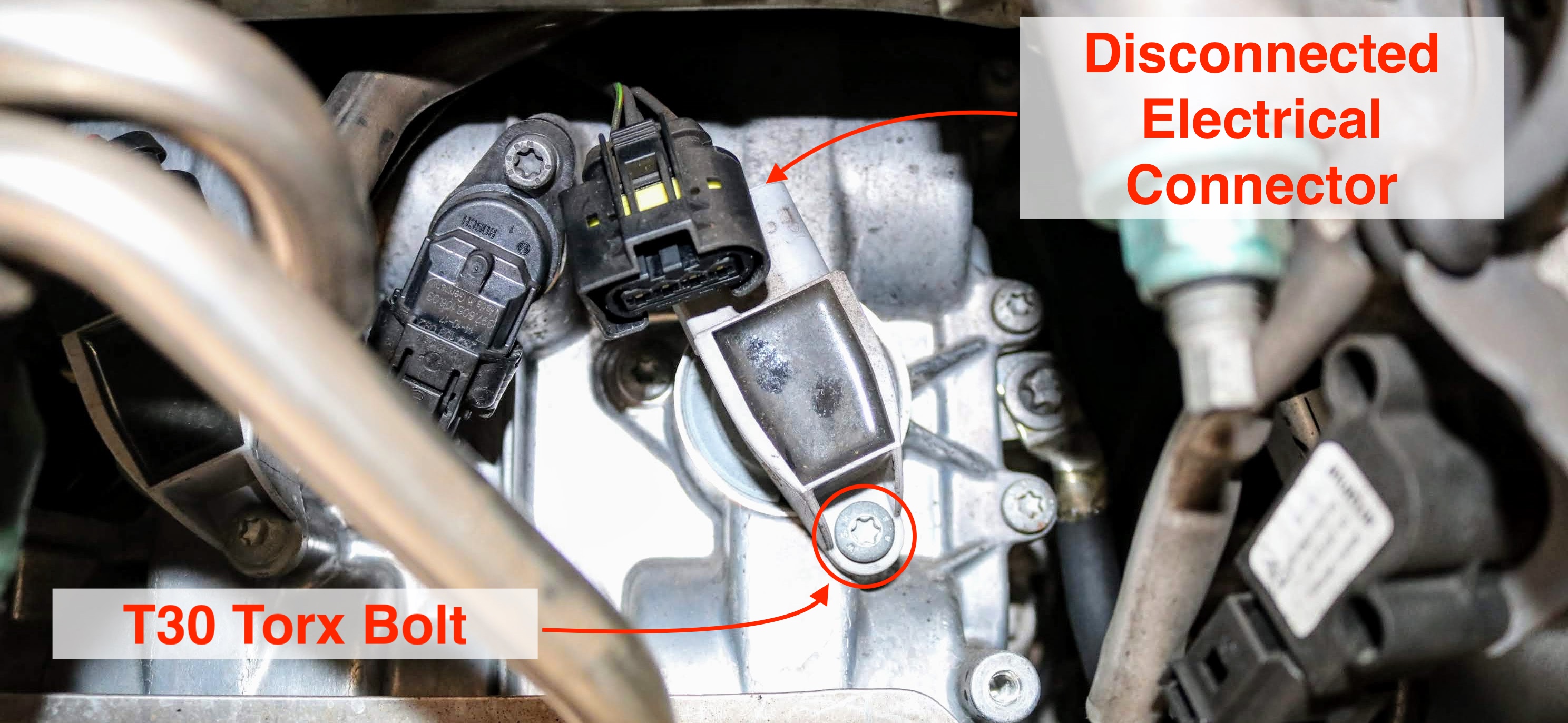

| T30 (Torx) Socket | Amazon |

| 16 mm 6-Point Spark Plug Socket | Amazon |

| 10 mm 6-Point Socket, 3/8" Drive | Amazon |

| 10 mm Combination Wrench | Amazon |

| Craftsman 3/8" Drive Extenable Ratchet 1 | Amazon |

| Milwaukee 3/8" Powered Ratchet 1,2 | Amazon |

| 1/2" Drive Ratchet 3 | Amazon |

| 1/2" Drive Torque Wrench 3 | Amazon |

| 19 mm 6-Point Socket, 3/8" Drive 3 | Amazon |

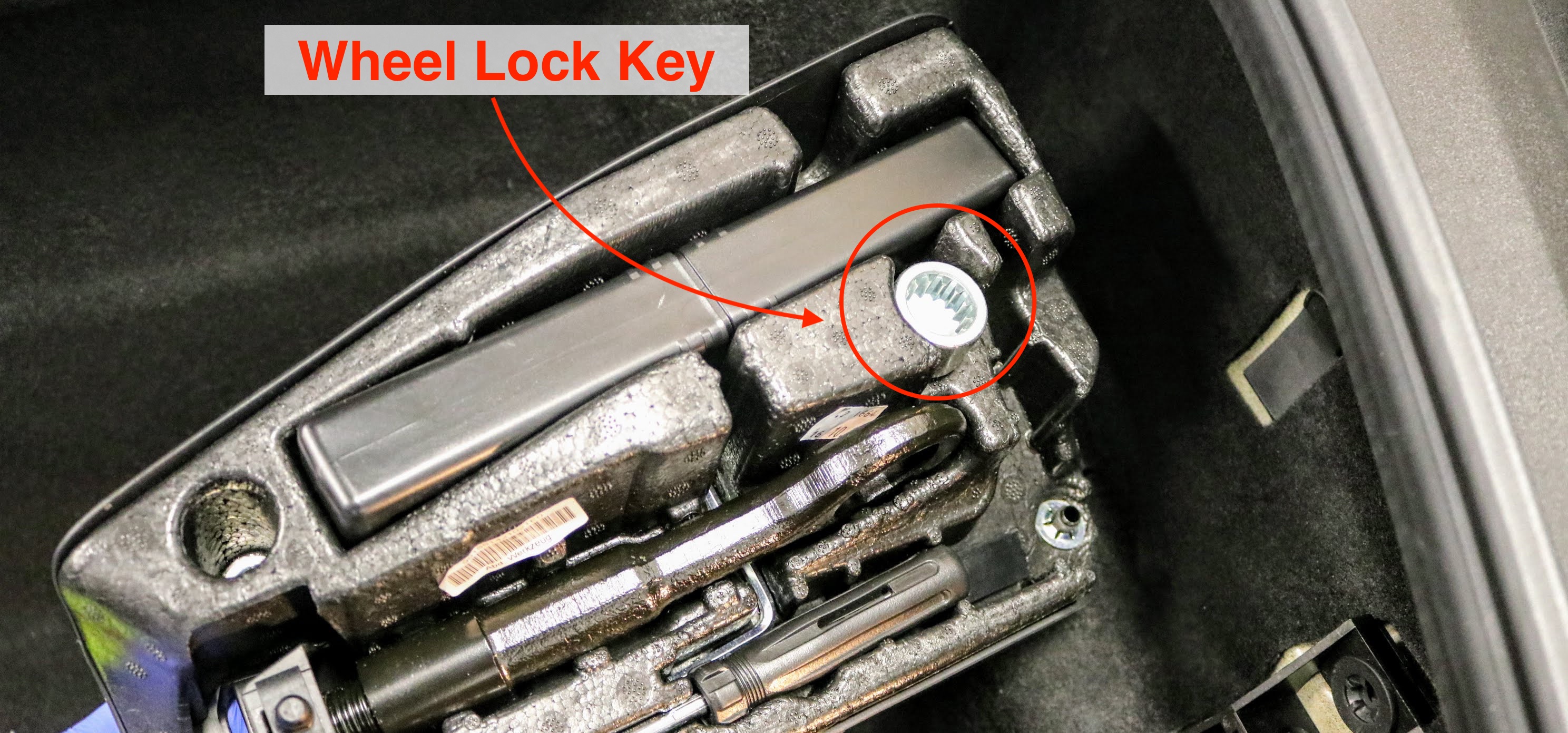

| Porsche Wheel Guide 3 | Amazon |

| DeWALT 1/2" Impact Wrench 1,3 | Amazon |

1 Not necessary to complete this job, but sure makes it a lot easier!

2 Use only for removing bolts/nuts and

3 Used for wheel removal (not pictured)